VOC Concentrator

Taikisha USA Inc. offers VOC Concentrators for air pollution control on paint booth exhausts.

VOC Concentrator

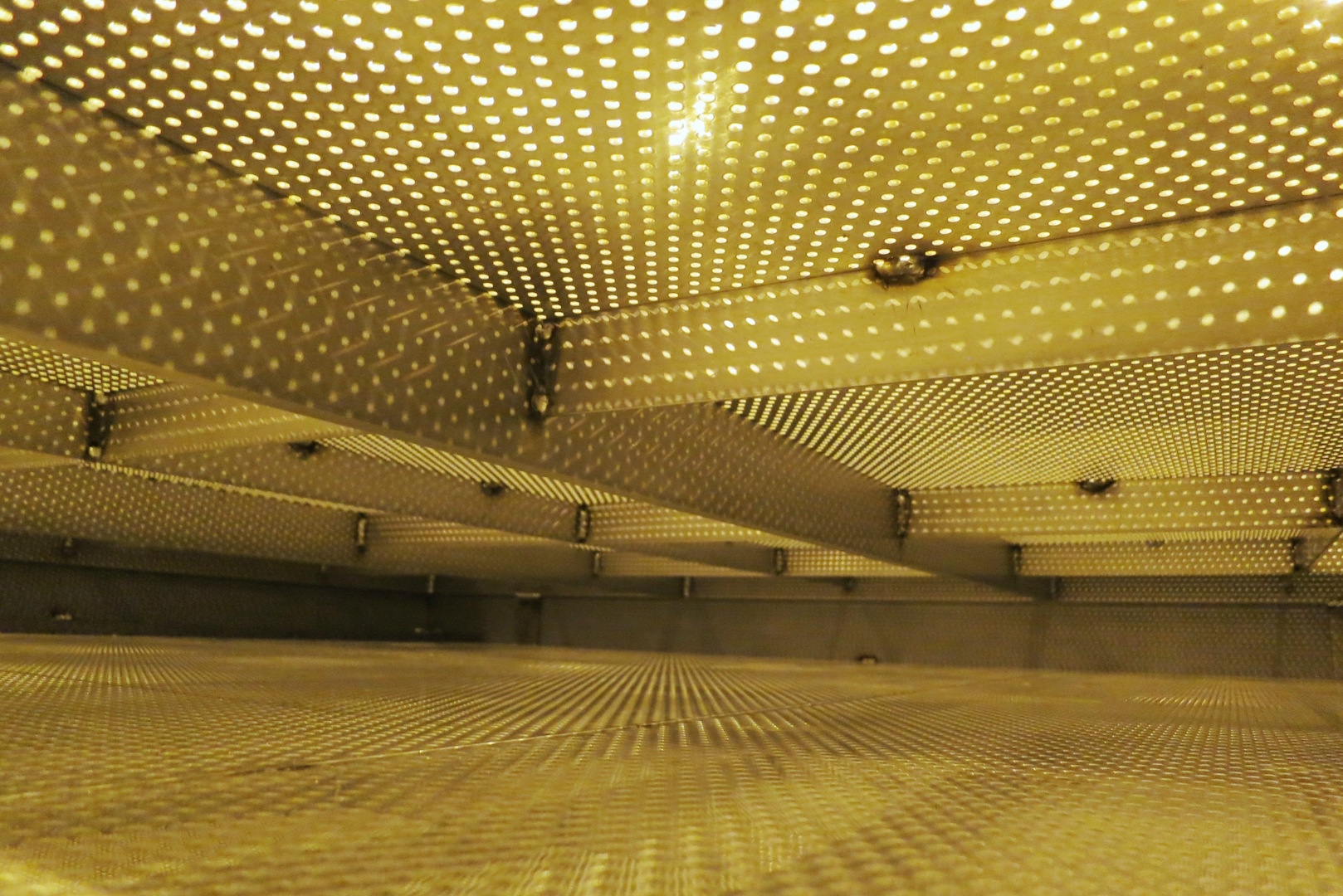

The VOC Concentrator is an activated carbon or zeolite adsorption system designed to capture and destroy volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) from industrial process exhausts.

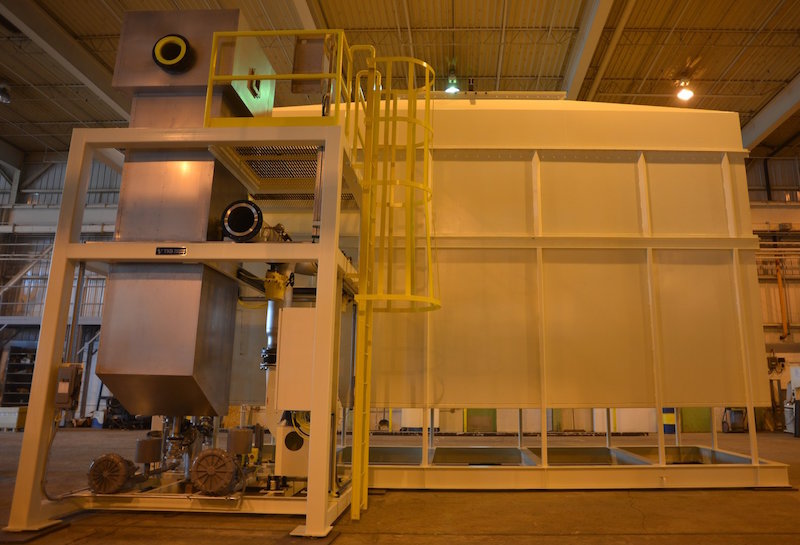

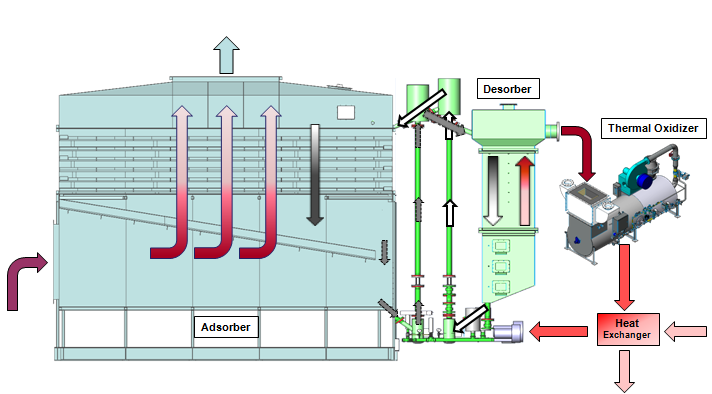

A concentrator system consists of three main phases: Adsorbing, where the VOCs are captured; Desorbing, where the VOCs are heated and released; and thermal oxidation, where the VOCs are destroyed. The Adsorber and Desorber skid are show at right or below.

VOC Concentrator Operation

A VOC Concentrator system consists of three main pieces of equipment and three primary process steps:

- Adsorption: Exhaust air from manufacturing or industrial processes carrying VOCs & HAPs is propelled through trays containing small carbon beads; the pollutants and emissions are captured (adsorbed) by the activated carbon beads.

- Desorption: The VOC-laden "spent" carbon is pneumatically transferred to the Desorption Tower where it is heated to ~400$deg;F and the VOCs are released into a small volume air stream.

- Thermal Oxidizer: The small volume air stream with concentrated VOCs is sent to a thermal oxidizer where the concentrated VOCs are decomposed at temperatures of ~1450°F.

A heat exchanger is used to recovery waste heat from the thermal oxidizer and heat the fresh air coming in to the desorber. An optional heat exchanger can be used to use the incinerator's waste heat to warm the air coming into the oxidizer, making the thermal oxidizer into a recuperative thermal oxidizer.

Reduced-size Thermal Oxidizer

The key feature of the VOC Concentrator technology is a smaller thermal oxidizer, saving energy costs.

Reduced Energy Use

Up to 80% reduction in natural gas usage, when compared to an RTO, and up to 65% reduction in electricity, depending on inlet conditions.

Reduced Capital Costs

A VOC Concentrator or Rotor Concentrator system needs a smaller thermal oxidizer than a traditional RTO or Regenerative Catalytic Oxidizer (RCO). A smaller thermal oxidizer costs less, reducing the required capital investment and saving you money upfront.

Increased Reliability

No shutting down production due to a faulty RTO valve or broken rotor wheel. Fewer moving parts means more up time.

Manufacturing or Industrial Process Exhausts with VOC Emissions

VOC Concentrator systems are used in the paint booth, coatings, semiconductor, electronics, materials, food processing, furniture, printing, and solvent recovery industries.

Exhausts containing VOCs & HAPs

Our VOC Concentrator system works best for industrial exhausts containing airborne & gaseous organic solvents, VOCs, HAPs, and other volatile organics. Inorganic waste gases such as H2S, ammonia, and acid gases are a better fit for a gas scrubber.

Our VOC Concentrator system works best for industrial exhausts containing airborne & gaseous organic solvents, VOCs, HAPs, and other volatile organics. Inorganic waste gases such as H2S, ammonia, and acid gases are a better fit for a gas scrubber.

Avoid these situations

VOC Concentrator doesn't work with exhaust temps above 120°F, exhausts containing alcohols with low boiling points or long-chain organics with high boiling points. Customers should also avoid non-volatiles and compounds prone to polymerization or joining reactions with other exhaust chemicals.

Concentration Ratios of 10:1 to 1000:1

Unlike a traditional rotor concentrator that is limited to a 20:1 concentration ratio, the VOC Concentrator system and achieve concentration ratios in the hundreds if air is used as the desorption flow gas or the thousands if pure nitrogen is used as the desorption flow gas.

Energy use reductions up to 80%

When replacing a large RTO system, an VOC Concentrator system can offer a reduction in energy usage up to 90%, depending on the size of the equipment. One customer successfully achieved an 80% reduction in energy usage when switching from a 100,000 cfm RTO system to a 100,000 cfm dual-Adsorber VOC Concentrator system at their Alabama plant.

Frequently Asked Questions

About VOC Concentrator

.jpg)

Most batches of carbon last about one year, but it does vary some based on the solvent loading, total run time, and type of solvents, particularly the percentage high boiling point solvents.

Smaller VOC Concentrator systems can fit in a 25' x 25' area, but medium-to-large VOC Concentrators require a 30' x 30' area.

The VOC Concentrator system has been installed over 10 times since introduction at four different Fortune 500 companies.

Taikisha USA Inc. Offers

VOC Concentrator Service Packages

Turn-key Equipment Installation

Let Taikisha USA handle every aspect of your project from start-to-finish.

Monthly On-site

VOC Concentrator Assessments

Taikisha USA offers monthly, quarterly, and yearly VOC Concentrator health check assessments to evaluate performance, carbon life, and perform critical preventative maintenance tasks. Let the VOC Concentrator experts handle the maintenance for you.

Purchase New Beaded Activated Carbon

Ready to reactivate your beaded activated carbon or need to purchase new carbon? We're here to help with quick turnaround times.

Troubleshoot Equipment

Having a problem with your VOC Concentrator? Our VOC Concentrator experts and engineers are always available to help.

Pay-by-the-day consulting services

Need an VOC Concentrator expert to come to your plant location to help for the day? No problem. Our engineers are available to help out for a minimal daily fee.

Access to TKS Engineering Team

If you need help, advice, or expertise, the Taikisha Engineering team is always available to assist our VOC Concentrator customers.